Multipass Test Bench

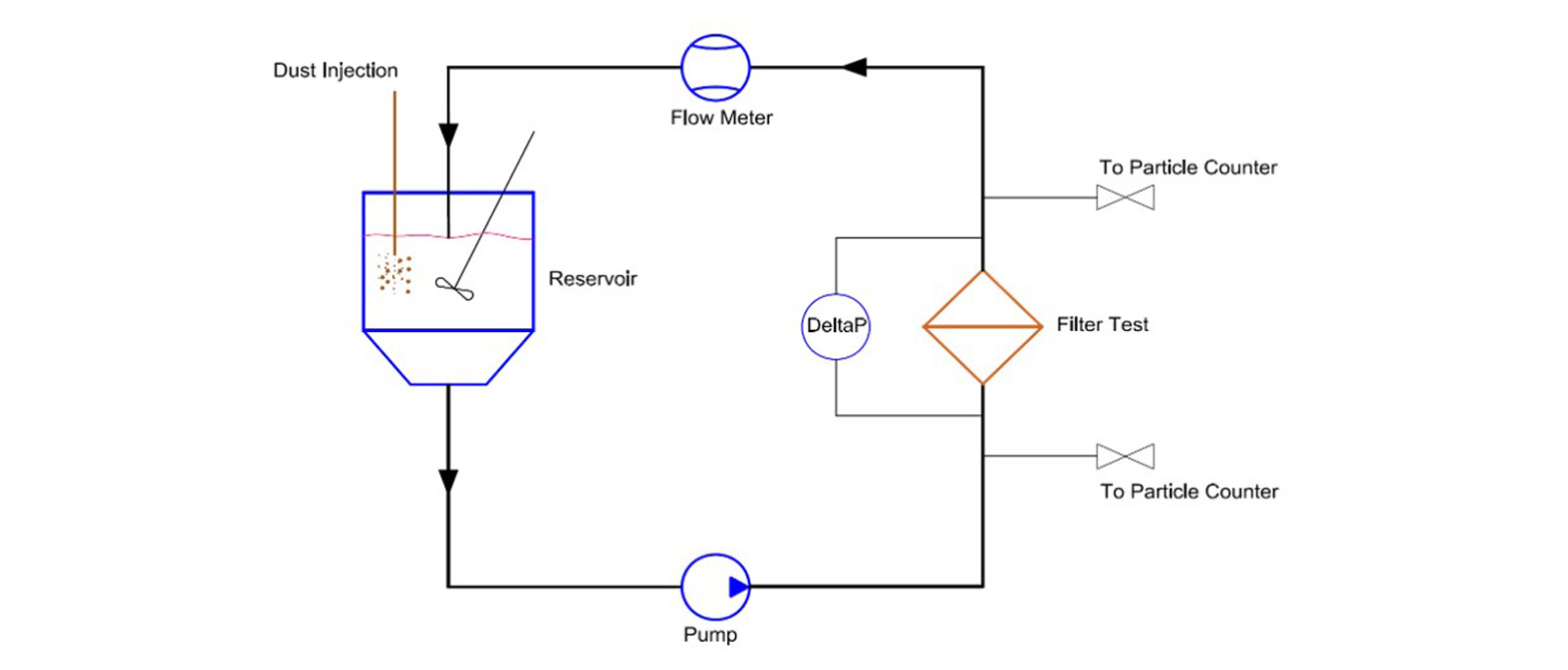

The ISO 16889:2022 standard outlines the procedure for testing hydraulic filter elements for their ability to remove solid contaminants from hydraulic fluids using a multipass test bench. Here's an overview of a multipass test bench according to ISO 16889:2022:

- Purpose: The primary purpose of a multipass test bench according to ISO 16889:2022 is to evaluate the filtration efficiency and performance of hydraulic filter elements. This is crucial in ensuring that hydraulic systems operate effectively and maintain the required levels of cleanliness.

- Test Fluid: The test bench uses a specified hydraulic test fluid with known contaminant levels. ISO 16889:2022 provides guidelines for the selection and preparation of this test fluid to simulate real-world hydraulic system conditions.

- Contaminant Injection: Contaminants of known particle size and concentration are injected into the test fluid. This is done to simulate the presence of solid contaminants that hydraulic filters are designed to remove.

- Multipass Circulation: The test fluid is continuously circulated through the hydraulic filter element being tested in a multipass loop. This simulates the operation of a hydraulic system where the fluid is repeatedly filtered.

- Data Collection: The test bench collects data on various parameters, including pressure differentials across the filter, flow rates, and contaminant levels in the test fluid before and after passing through the filter element.

- Performance Criteria: ISO 16889:2022 specifies performance criteria, such as the minimum filtration efficiency and the filter's dirt-holding capacity. The filter element must meet these criteria to be considered effective.

- Reporting: Results of the test, including data and analysis, are documented in a report. This report provides information on the filter element's performance, and it may include details on pressure differentials, particle counts, and other relevant measurements.

- Contaminant Retention Efficiency: The test bench assesses how well the filter element retains contaminants of specific sizes, typically in micron (µm) ratings, to determine its filtration efficiency.

- Repeatability and Reproducibility: ISO 16889:2022 emphasizes the importance of ensuring that test results are repeatable and reproducible. This requires rigorous testing protocols and well-maintained test equipment.

- Compliance with ISO 16889:2022: A multipass test bench according to ISO 16889:2022 must adhere to the standard's specific testing procedures and criteria to ensure that hydraulic filter elements are tested consistently and accurately.

In summary, a Multipass Test Bench is mainly used for testing the performance of hydraulic filters according to the ISO16889:2022, ISO19438:2003, ISO4548:2017 and ISO3968-12:2017. The test bench is full automatically controlled by computer, the screen can display the flow chart and all the test parameters. All the data will be saved in order automatically by the computer. Data handling and generate reports according to the ISO16889:2022, ISO19438:2003, ISO4548:2017 and ISO3968-12:2017 are included.